Usage

It's especially used in aboveground coal washeries, power plants, and non-coal underground mining. For general use with electrical and fire safety requirements to EN 12882.

Characteristics

The product is made of nylon canvas or EP canvas and finished through the processes of calendering, assembling, vulcanizing, etc. The unique formula enables it to work continuously in a flammable environment.

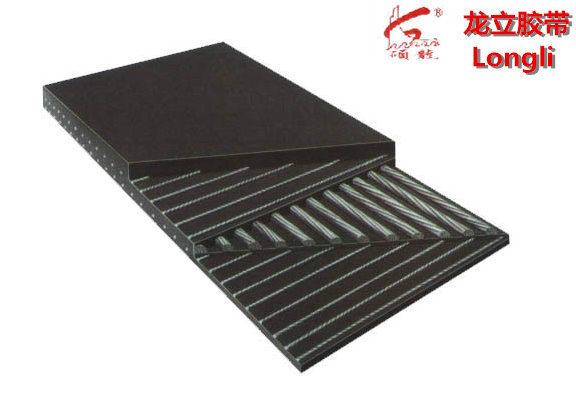

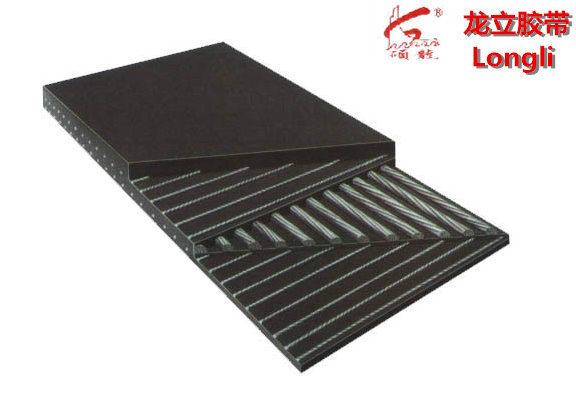

Structure

Standard Specifications

| Strength grade | Tensile strength (KN/m) | Cord pitch (mm) | Cord diameter (mm) | Min. breaking force (KN) | Min. cover thickness (mm) |

ST-500

| 500

| 10

| 2.5 | 5.5 | 4

|

ST-630

| 630

| 10 | 2.8 | 7

| 4 |

| ST-800 | 800

| 10

| 3 | 8.9

| 4

|

| ST-1000 | 1000 | 12 | 3.7 | 12.9 | 4 |

| ST-1250 | 1250 | 12 | 4.2 | 16.1 | 4

|

ST-1400

| 1400

| 12

| 4.3 | 18

| 4

|

ST-1600

| 1600

| 12

| 4.7 | 20.6

| 4

|

ST-2000

| 2000

| 12

| 5.3

| 25.6 | 4 |

ST-2250

| 2250 | 12 | 5.3 | 29

| 4 |

ST-2500

| 2500

| 15 | 6.8

| 40

| 5

|

ST-2800

| 2800 | 15

| 7

| 44.8 | 5

|

ST-3150

| 3150 | 15

| 7.8 | 50.5

| 5.5

|

ST-3500

| 3500 | 15

| 8.2

| 56

| 6

|

ST-4000

| 4000 | 15

| 8.8

| 63.6

| 6.5

|

ST-4500

| 4500

| 16 | 9.7

| 76.3

| 7

|

ST-5000

| 5000

| 17 | 10.9 | 91

| 7.5

|

ST-5400

| 5400

| 17

| 11.3

| 98.2

| 8 |

ST-6300

| 6300

| 19.5

| 12.8

| 130.4

| 10

|

ST-7000

| 7000

| 19.5

| 13.5

| 142.4

| 10

|

ST-7500

| 7500

| 21

| 13.8 | 166.7

| 10

|

ST-8000

| 8000

| 21

| 14

| 180.9

| 10

|

ST-9000

| 9000 | 21

| 14.8

| 203.2

| 11

|

ST-10000

| 10000

| 21 | 15.5 | 225

| 11 |

Cover Properties

| Grade | Tensile strength min.(ISO37)Mpa | Elongation at break min.(ISO37)% | Abrasion max.(ISO4649)m m3 |

D

| 18

| 450 | 200

|

L

| 14 | 400 | 250 |

Safety Properties

| Items | Flame resistant grade |

| K2 | K3 |

| Duration of flame | The total duration of flame of 6 testpieces with covers is less than45S,any individual test piece does notexceed 15 S | Average value of duration of flameof 3 test pieces with covers doesnot exceed 60S |

| Anti-static property | ≤3 x 108 Ω |

| Reapperance | There should be no reappearance of flame on any test piece. |